BIOGENIC REFINERY TECHNICAL DESCRIPTION

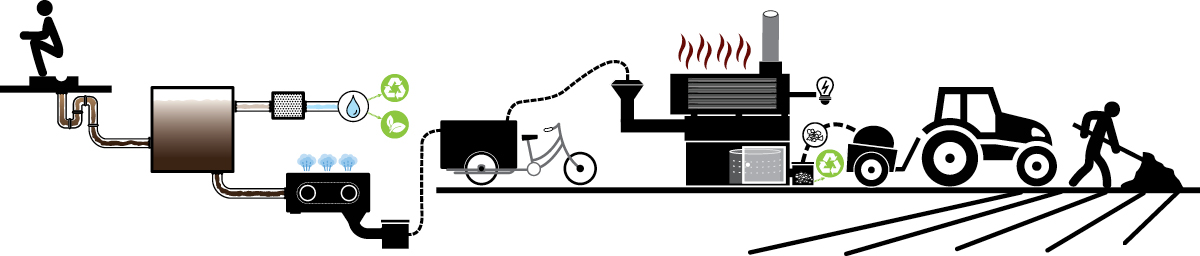

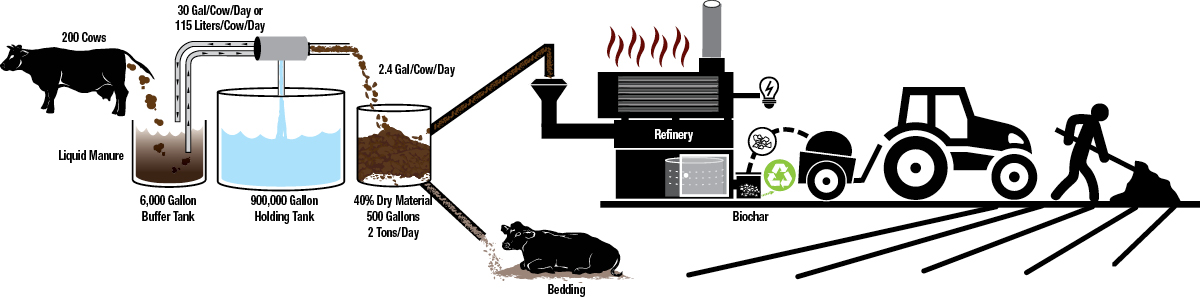

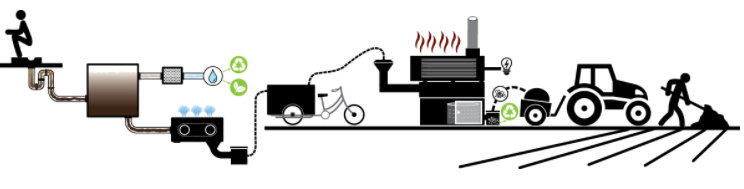

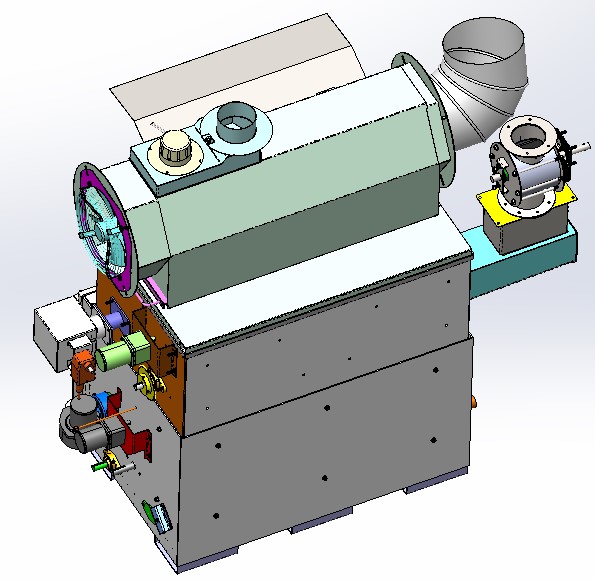

The Biomass Controls Biogenic Refinery (BR) is a small-scale processor, capable of refining any biogenic matter into inert carbon with significant volume reduction, carbon sequestration in the form of biochar, and controlled emissions. The BR uses a continuous, efficient pyrolysis-combustion system to instantaneously inactivate all pathogens while producing thermal energy useful for drying and value added biochar with a volume reduction of approximately 90% over original feedstock. Each BR is capable of processing up to 960 kg (assuming 24 hours of runtime) of organic waste per day on a dry basis, converting to up to 173 kg of biochar.

The Biogenic Refinery occupies a small footprint, but is packed with emerging technologies that provide cost-effective process efficiency, greenhouse gas (GHG) emissions reductions, economic, and environmental benefits.

Biogenic Refinery Benefits

- • RAPID AVAILABILITY, SCALABILITY

A small footprint and modular design allow for fast deployment. Distributed and cascaded systems deliver high availability and scalability from 10 to 35,000 people.

- • EFFECTIVE TREATMENT

Pathogens are inactivated within 24 hours by the pyrolysis-combustion process, and a volume reduction of 90% is achieved on a dry basis.

- • VALUABLE TREATMENT PRODUCTS

Biochar can be used as a soil amendment, for filtration, cooking or heating. Thermal energy can be used for pasteurization and drying of the feedstock and for electricity generation.

- • REMOTE PERFORMANCE MONITORING

The kelv˚n software platform offers real-time reporting and alerts to operators and supervisors, allows for remote monitoring and provides user interaction through a mobile or web interface.